Executive summary

Installing a heat pump often requires additional steps beyond simply fitting the unit. This adds complexity and cost, which can deter homeowners, especially when a quick gas boiler swap is often easier. We explored whether some of these steps could be addressed in advance, to make it easier to switch to a heat pump later.

Major changes, such as resizing radiators or creating space for a hot water cylinder, are best done when disruption is already planned, for example, during renovations. Regulation could accelerate this shift by requiring low-temperature suitable radiators and pipework at boiler replacement or during major renovations, but such an approach risks adding unnecessary cost, especially if high-temperature heat pumps become the norm.

A more practical route is to help homeowners understand what ‘heat pump readiness’ means for their home, encouraging them to take small, timely steps when it suits them. Embedding clear, trusted guidance into everyday moments such as renovation, homebuying or boiler servicing could help many start the journey earlier and avoid locking in features that make future heat pump installations harder or more expensive to run. Any such adjustments done in advance need to offer a clear benefit to homeowners and eliminate – rather than add – hassle.

At the same time, streamlining processes (such as Distribution Network Operator approval, electricity supply upgrades and the Energy Performance Certificate requirement for BUS funding) is crucial to making homes administratively ready for a heat pump.

As heat pump uptake accelerates, ensuring both households and the grid are ready will determine whether low-carbon heating can be the default, particularly at moments of boiler breakdown. Making homes more ready for heat pumps is unlikely to be a silver bullet – cost and awareness will still be major barriers – but we are confident that a combination of system-level improvements and targeted guidance for homeowners can make heat pumps meaningfully easier to install for many households.

Read the accompanying report

Identifying barriers to air source heat pump adoption

What do households need to be ready for a heat pump

What do households need to be ready for a heat pump?

Heat pumps will replace boilers in the majority of the UK’s homes. It is estimated that 22.8 million of the UK’s 29 million existing homes (~80%) will have a heat pump by 2050. However, many homes, while technically suitable for a heat pump, are not ready to have one installed immediately without some additional steps.

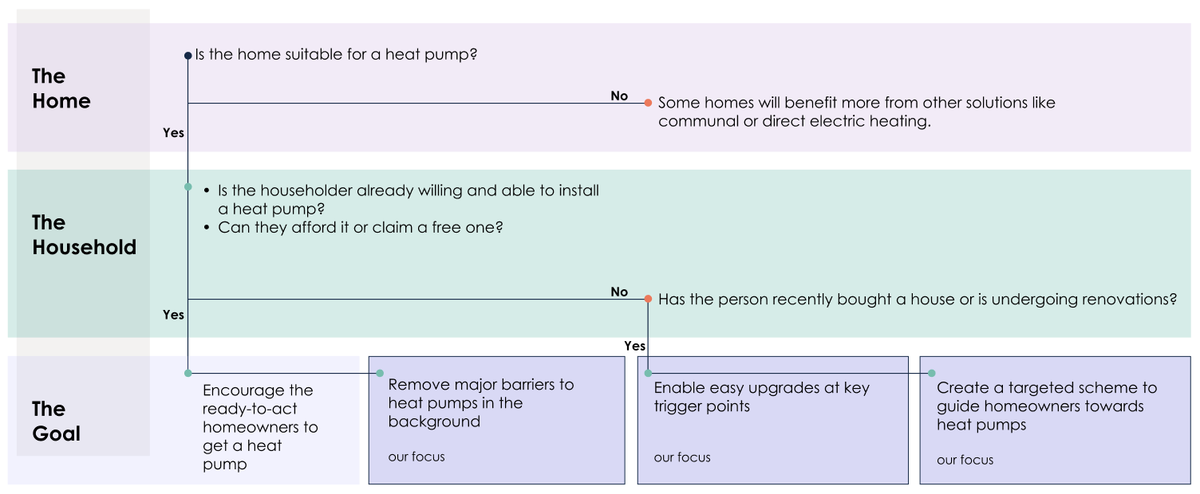

Whether or not a household is ready for a heat pump broadly depends on three things.

- Is the householder ready to get a heat pump?

- Does the home have the right physical conditions for a heat pump?

- Have the relevant administrative conditions been met?

Together, these factors determine how ‘heat pump-ready’ a household is.

Is the householder ready? Households need to know about heat pumps and be motivated to switch to one. They also need access to funds or finance to pay for a heat pump.

Householder readiness

Is the home ready? The physical state of the property plays a major role. Some steps are necessary while others are desirable. Government data suggests that 80–90% of UK homes already have enough insulation to run a heat pump, but like any heating system, improving insulation and draught-proofing can lower running costs.

There is no universal minimum threshold for the level of insulation that a home needs before installing a heat pump. Homes with less insulation will be more expensive to heat, and some experts are concerned that installing heat pumps in these homes risks undermining their reputation and limiting wide-scale adoption. Others are increasingly relaxed about the amount of insulation needed, and are advocating for less disruptive installations with higher temperature systems as a way to scale adoption. One example of this trend is the elimination of insulation requirements from the Boiler Upgrade Scheme in 2024. Measures that reduce running costs can be installed after a heat pump is in place.

Heat pump readiness of the home

Are other requirements met? Getting a heat pump may require approval from the local Distribution Network Operator (DNO). Other procedural steps may include getting an Energy Performance Certificate (EPC), a heat loss survey, and planning permission.

Meeting other requirements

Why should homes get ready for a heat pump?

Many of the adjustments needed for a heat pump installation are individually small, but they can add up to considerable additional cost and stress if they all need to be done at the same time. As a result, there are many points where even households motivated to get a heat pump drop out of the journey and opt for a replacement boiler instead. This delays their transition to a heat pump by many years.

The requirements detailed above pose an even bigger barrier to households that only replace their heating system when the old one breaks, ie, a ‘distressed purchase’. According to Which?, three-quarters of homeowners wait until a breakdown before making a decision, and in that crisis moment, they are likely to default to the quickest, most familiar option: either repairing their existing gas boiler or getting a new one.

The complexity of heat pump installations is compounded by a lack of awareness – 45% of people have either never heard of a heat pump or don’t know what heat pumps are, according to surveys by DESNZ and Nesta. Even fewer understand what an installation involves.

- One in three homeowners say they might consider a heat pump if they need to change their heating in the next year.

- Only 15% of homeowners would consider a heat pump if their boiler breaks tomorrow. However, 35% of those who did some research before installing new heating said they actively considered installing a heat pump.

A lack of understanding about what a heat pump installation entails often leads households to make counterproductive choices that make it harder to install a heat pump in the future. For example, removing their hot water cylinder when they install a combi boiler.

If preparatory work is already complete when a homeowner needs to replace their heating, the overall hassle and cost associated with a heat pump is lower. This increases the likelihood of completing a heat pump installation. While not all upgrades are practical to do in advance, due to disruption or uncertainty, some steps can be taken early.

The government has set a goal to allow heat pump installations within 3 days of a final quote. Making homes more ready is a way to achieve this. It will not be a silver bullet – cost and awareness will still be major barriers – but it can make a meaningful difference for some households. On the next page, we explore what ‘making homes heat pump ready’ could entail and what impact that could have on heat pump adoption.

Our hypothesis

Every heat pump installation involves some amount of additional work beyond fitting the unit itself. Some steps are essential (eg, sufficient electrical supply), others are optional but beneficial (eg, extra insulation and solar panels).

If homeowners can complete some of these steps gradually, the transition to a heat pump becomes easier, cheaper, and less disruptive. Making homes and households ‘ready’ for heat pumps should accelerate the shift away from gas boilers.

What we learned from households

What we learned from households

To understand what ‘heat pump readiness’ means in practice, we spoke with 14 homeowners across the UK, from those living in rural detached homes to city terraces. We explored how they think, plan, and act around their homes, and what might make them consider a heat pump.

Across conversations, the message was consistent: people don’t think about heating until something goes wrong. Heating systems sit quietly in the background, noticed only when they fail or cause discomfort. When that happens, decisions are fast, emotional, and nearly always end with another gas boiler. It makes sense for households; it is quick, familiar, and restores warmth.

If most people only act at the point of crisis, then readiness must happen earlier. This means small, timely steps that make future changes smoother and cheaper.

How households think about heating and change

Who should readiness be aimed at

Many households have a pressing need for clear advice about switching to a heat pump. People tend to be more open to heating advice when they are buying a home, or planning renovations, or when their boiler is still working but showing its age. These are natural moments when households are already thinking about their property, likely more willing to spend money, and open to some disruption. Taking steps to make their home more ready for a heat pump can feel like good timing, rather than extra work. Three key groups are in a good position to make their homes “heat pump ready”.

Homebuyers are often already reviewing surveys and EPCs, with many planning renovations soon after purchase. Providing more information about heat pump readiness at this stage could help them spot opportunities or avoid undoing progress, such as removing a hot water cylinder or choosing undersized radiators. First-time buyers tend to be focused on affordability, whereas second-time buyers are often more established and stay in their homes for longer, which might make them more receptive to readiness advice.

Motivated by comfort, layout, or design, renovators are already spending time and money on disruptive upgrades. Heat pump readiness advice can provide “do-it-while-you’re-there” actions and prevent future rework, for example, upgrading wiring or keeping cylinder space. With all the changes listed above, we would anticipate households would only implement these measures if they are already undertaking major works. Otherwise, the additional disruption and cost associated with builders coming into the home would most likely not be worth the benefits.

When a boiler is old but not yet broken, people start noticing small issues and can become more receptive to future-focused advice, such as simple checks or guidance on what to do next. Light-touch readiness prompts during maintenance, such as checking radiator size or electrical capacity, could plant seeds for future decisions.

Testing ‘readiness as a service’

To explore how readiness might work in practice, we prototyped a heat pump readiness report – a tool that gives homeowners a personalised view of how prepared their home is and what steps they could take next. We conducted user testing of the initial prototype with five people.

Heat pump readiness prototype

The goal was to use the tool as a prompt to understand how households interpret heat pump readiness: what actions it implies, what they might do next, and how they perceive the effort and cost involved. We also explored whether it changed how feasible a heat pump felt, what further information or reassurance they might need, and when such guidance would be useful.

- People reported that the report helped them to see heat pumps as a more tangible and relevant option for their homes. They tended to regard it as a practical planning tool, something to keep and refer to when doing other work. Our testing suggested the report supported their understanding of potential upgrades and what might make sense to do ‘while you’re there’.

- New radiators stood out as a particularly relatable starting point for many people. This is because it is a step they can take that can directly improve their comfort. However, multiple people we spoke to wanted a clear explanation of the cost of installing new radiators and the disruption it might cause.

- Many people wanted reassurance that tradespeople and other professionals would recognise and trust the advice in the report in the future.

This exercise also revealed a deeper challenge: coordination fatigue. Even with clear steps, homeowners often felt overwhelmed by the number of actors involved. “Does one person help with all of these?” was a common question.

- People reported they were most confident tackling steps they had done before, such as insulation and radiators.

- More technical steps, like checking their electricity supply, felt daunting for some. For many, the combined effort seemed too much: “I have two young kids, work full-time… when do I do that?” “I’m super busy, have two little kids, I have so little time to arrange or look into things.”

- This speaks to a core question about how readiness could work in practice: to what extent does staggering the work reduce the perceived effort for households? When these works are done alongside a heat pump installation, the works are often all organised by the heat pump installation company. Staggering works over time may impose a greater burden on householders compared to doing them all together at the point of installing a heat pump.

Across our interviews, three broad mindsets shaped how households approached heat pump readiness:

Segmenting households by mindset

What readiness could unlock for households and what this means

Across all three of our mindsets, there were four potential benefits which stood out. These benefits show how readiness can meet households where they are: building awareness among the unconvinced, supporting the planner to act gradually while work is already underway in their homes, and enabling the ready-to-act to move more confidently through fewer steps. When we had these conversations, we did not have a single policy or product that defined ‘readiness’. Our discussions revealed three challenges for any future policies or services:

Benefits vs challenges

How to get homes more ready for heat pumps? (part 1)

How to get homes more ready for heat pumps?

We outline several potential avenues for the market and government to enhance household readiness. These approaches focus either on promoting individual actions or providing households with information to facilitate better planning. We briefly examine the potential policies and services, their anticipated impact, and their relative ease of implementation.

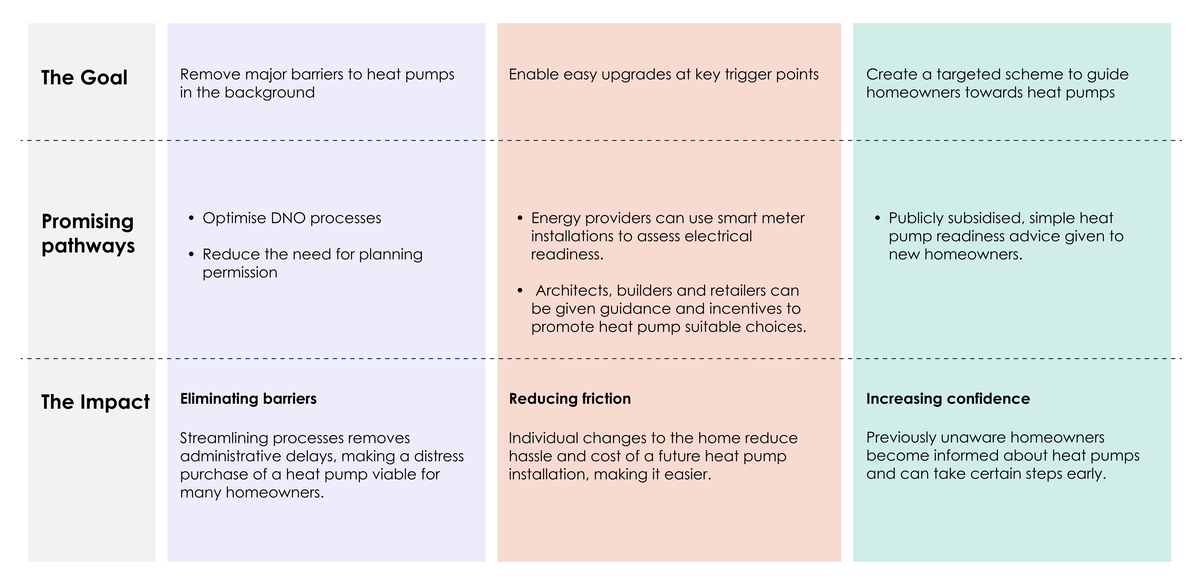

1. Remove major barriers to heat pumps in the background

Once homeowners are in the process of getting a heat pump, the longest delays tend to be due to required steps outside of their control – getting approval from the local Distribution Network Operator (DNO) (very common) and receiving planning permission (less common).

1a. Optimise DNO approval

DNO approval can add weeks of waiting time to installations. Average approval time for a heat pump installation ranges between 2 and 4 weeks under different DNOs. Recent data shows that for a significant proportion of installs, the complete process takes over a month. Waiting times are due to inefficiencies in communication between installers and DNOs, and often due to the time it takes to deliver upgrades to fuses or to unloop the property from neighbours.

Getting homes ready before a new connection happens would eliminate a significant barrier for households.

SSEN (one DNO) is currently trialing a Low Carbon Technology (LCT) connection readiness indicator. It allows customers to find out whether their home is ready for electrification on a public platform and proactively request an upgrade from their DNO if needed. This is a small but positive signal of where the system should progress towards – accurate and open data about properties, used by installers, local authorities and retrofit coordinators, with upgrades offered proactively by DNOs free of charge to the customer.

To support the Warm Homes Plan’s ambition for proactive unlooping and a 5-day turnaround, the current DNO approval process must be streamlined to reduce response times and improve compliance from installers. Ofgem has an opportunity to embed this proactive approach within the forthcoming RIIO-ED3 price control system. Solutions could include embedding faster heat pump connections into the KPIs of DNOs that are linked to funding, improving DNO data quality to quickly assess the need for upgrades, and further standardising the application process.

In addition to speeding up approvals, if DNOs start playing a more active role in local planning and delivery of low-carbon technologies (in partnership with local governments), then their data, paired with data about heat pump suitability of homes, could be used to prioritise which homes to upgrade proactively.

1b. Reduce the need for planning permission

Across Great Britain, residential air-source heat pumps fall under Permitted Development Rights (PDR). This means they can be installed without planning permission, as long as they meet certain conditions. Homes that do not meet those conditions have to submit a planning application, which is a significant deterrent for homeowners and installers. This process can be complex, expensive and take months.

The UK government's recent reforms to England’s PDR – removal of the one-metre boundary rule, increased size limits for units, and more flexibility for detached homes – represent vital progress. However, planning rules continue to be a point of friction for a significant number of homes, in part due to some of the remaining PDR restrictions on heat pumps. The government will consult on further changes to permitted development in 2026.

To reduce many of these remaining points of friction and accelerate deployment, further specific liberalisations to the PDRs are required. Outside of Conservation Areas, siting restrictions should be relaxed to allow installations on pitched roofs, on flat roofs within one metre of the edge, and on upper-storey walls fronting a highway, as well as permitting co-location with wind turbines.

As is now the case for detached houses, more than one heat pump should be allowed to be installed for semi-detached and terraced houses as long as the cumulative sound level of the installs meets the current limit set under MCS020.

Regarding heritage constraints, PDR for the existing rules for conservation areas could be adapted to include listed buildings (meaning these households only have to apply for listed building consent). In conservation areas, rules should be relaxed to allow for units to be sited closer to the highway than the dwelling or on highway-fronting elevations as long as they are on the ground floor and sited to minimise visual impact. Finally, to eliminate regulatory ambiguity, subjective clauses requiring the ‘minimisation’ of visual and amenity impacts should be removed for areas outside of conservation areas and for listed buildings.

We are also currently investigating the current calculation being used to assess compliance with the sound limit. The UK Government has acknowledged that it may be too conservative and needs revision.

1c. Remove the EPC certificate as a condition for BUS funding

Finally, homeowners currently (2025) need an EPC issued in the last 10 years to access the Boiler Upgrade Scheme (BUS). Depending on availability, getting an EPC assessment can delay an installation by up to a week and requires another home visit and extra costs. The EPC quickly loses its relevance as it is out of date as soon as the heat pump is installed.

Around half of all properties do not have a valid EPC and need to apply for one to access BUS. If EPCs of all ages were permissible for BUS, that would cover around 70% of properties.

The government recently announced that BUS applicants will now be able to submit ‘alternative forms of evidence’ in place of obtaining new EPC certificates. This should eliminate one existing friction point and allow some households to install a heat pump quickly (as a ‘distress purchase’) if their home is otherwise ready.

How to get homes more ready for heat pumps? (part 2)

2. Enable easy upgrades at key trigger points

There are some key ‘heat pump readiness’ changes to homes that require homeowners' active involvement. We want to make these easier to do in advance, or more routine, to take away some cost and effort from the actual moment of installing a heat pump.

2a. Incentivise low-temperature systems

Heating engineers often describe the transition to a heat pump as two-fold: first to a low flow temperature system (larger radiators and pipework) and then to a new heating source. Ensuring a home is fit for a low-temperature system makes a later heat pump installation smoother.

Key touchpoints could be used to move households onto low temperature systems (systems with radiators and pipework suitable for 55 degree flow temperature or below).

Boiler maintenance and repair. When a heating engineer is at a property, homeowners have an opportunity to learn about heating options and how to optimise their heating system. Some heating engineers already advise people to lower their flow temperature, install weather compensation or start thinking about radiator upgrades. However, due to the high number of individual engineers, it is difficult to influence the advice they give. Many gas engineers report not having the time or incentives to provide advice about heat pumps and low-temperature systems during routine appointments with households. However, we believe there is an opportunity here for vertically integrated companies that both install heat pumps and provide boiler servicing.

New boiler installations. If all new boiler installations were to include a transition to low flow temperatures, every installer would need to do a full heat loss calculation and fit new radiators if needed. As a result, over a million households every year would become one step more ready for a heat pump.

The additional work would add significant costs to new boiler installations. We could assume that about 7 out of 10 properties would need larger radiators to operate at lower flow temperatures, and they would replace 6 radiators on average (assumptions based on a 2020 survey of installers). If each radiator costs £200, the average price across all households would be £840. If each heat loss calculation costs around £250, the whole process would add almost £1,100 to the average boiler installation. At 1.7 million boiler installations per year, the total cost could be around £1.9 billion.

Part L of the building regulations for England already mandates all new heating systems to be designed to a maximum temperature of 55 °C. Extending the mandate to all changes to heating, including new boilers, would most likely require regulatory oversight and enforcement by the Gas Safe Register. Such a mandate would come with many challenges. The high cost compared to simple boiler replacements, if placed on consumers, would likely face significant resistance, especially since energy savings from more efficient gas systems tend to be small.

Low-flow temperature design could be mandated for all publicly funded retrofits (primarily through schemes like ECO). But it is difficult to justify a situation in which households eligible for free upgrades receive only marginal improvements to their heating systems, rather than progressing directly to the installation of a heat pump.

Making changes to the heating system for practical or aesthetic reasons. Another way to promote earlier radiator upgrades could be to introduce incentives for people renovating their homes. Radiators are currently zero-rated in terms of VAT if installed alongside a heat pump. This rule could be extended to all radiators installed as part of a low-temperature heating system, incentivising renovators to opt for adequately sized radiators.

The UK market for residential radiators is estimated at £252 million. If, for example, 10% were eligible, subsidising them at 20% (VAT) would add up to government cost of £25 million/year. However, the zero rate would be difficult to implement since it would need to rely on builders’ or sellers’ declarations and would technically require a heat loss calculation to show precisely what emitter sizes are needed for a particular home.

Major installers are trying to reduce the extent to which radiator upgrades are a critical step in the process. Services such as Octopus Turbo and Heat Geek Zero Disrupt focus on installing high-temperature heat pumps while limiting other changes. While these systems are less efficient, this suggests that preparing homes for low-flow temperatures could become less of a priority as the number of homes getting heat pumps increases.

We don’t currently see financial incentives or mandates for low flow temperatures as a practical route to heat pump readiness. The scale of enforcement required, the risk of fraud, and the added costs to households make this difficult to justify. There is also a real chance that these upgrades become less relevant as high-temperature heat pumps expand and radiator changes matter less. Overall, the returns look weak compared to directing support toward measures that help households move to a heat pump outright.

2b. Frontload electrical upgrades

Most installers subcontract electricians for upgrades to the home’s consumer unit, if needed as part of a heat pump installation. This adds time and cost.

These upgrades are possible to carry out in advance at points when there is already a qualified electrician in the home. For example, during a major renovation, when solar or batteries are being installed, or during repairs to lighting and appliances. The UK government could amend Part P of the Building Regulations (regulated separately for Wales and Scotland) to mandate that electricians check whether the home is ready for a low-carbon technology installation. If it is not, the electrician would need to inform the homeowner and offer to carry out the upgrade to the home’s electrics.

Another point where a homeowner engages with their electrical system is at a smart meter installation. Energy providers usually subcontract these to specialised smart meter installers. The easiest way for these to trigger electrical upgrades would be for the meter installer to do a simple visual inspection and report back whether an upgrade is necessary. The supplier could then coordinate with an electrician to do these electrical upgrades pre-emptively. Smart meter installations are sometimes the only point at which energy suppliers are in direct contact with their customers. Energy suppliers are likely to install a larger share of heat pumps in the future than they currently do. Some already own their own heat pump companies. As such, they are incentivised to build a pipeline of heat pump-ready customers who would be more likely to use them for a future heat pump or EV charger installation. Suppliers are already commonly installing isolation switches alongside smart meters where necessary.

Almost 250,000 smart meters are being installed each month (~3 million a year). If 20% of homes required a new consumer unit (no data available for this estimate), that would create 600,000 opportunities each year. With a 50% acceptance rate and if 80% of homes will need this to get a heat pump (CCC estimate), ~240,000 homes a year would become electrically heat-pump-ready through smart-meter visits.

Separately, there are ~3.5 million renovation projects each year, and surveys show ~60 % involve an electrician. Assuming the same rate of upgrades as above, this would yield more than 200,000 additional homes a year, becoming more ready.

Together, these touchpoints could deliver ~450,000 electrical upgrades per year, moving homes toward heat pump readiness. By shifting electrical upgrades to a time when an electrician is already on site, we estimate these homes would save £200–300 and 1–2 days on their heat pump installations.

However, we have heard anecdotally that many installers prefer to install an additional consumer unit when installing a heat pump, rather than upgrading the existing consumer unit. More work needs to be done to consider if encouraging upgrades to existing consumer units in advance of the heat pump installs is worthwhile, as it would be redundant if installers prefer to use additional ones.

2c. Nudge renovators towards heat pump readiness

Homeowners’ decisions affect their future heating options, often without them realising. The right advice, tools and incentives during or before renovations could make homes more ready for a heat pump. Below, we explore some promising touchpoints.

- Engaging an architect: People who hire architects are often already planning bigger changes and spending more. Focusing on architects’ continuing professional development, design checklists, or accreditation schemes could lead to more heat pump readiness. Home improvements could include always leaving space for a water cylinder, opting for larger radiators and designing for outdoor and indoor unit space.

- Working with consultants and builders: Mechanical and Electrical (M&E) consultants take practical decisions like pipe diameters and radiator sizes. A service could help them quickly assess whether a home’s systems are heat pump compatible, perhaps through a digital checklist. Builders could then recommend future-proof upgrades while floors or walls are already open.

- Shopping: Retailers influence thousands of small decisions every day – from which hot-water cylinder people buy to what advice they get in-store. Creating a ‘heat pump-ready’ product label or training staff to mention future compatibility could steer people towards future-proof choices.

Around 3.5 million households renovate their home each year (with £14,000 average spend). If only 1 in 20 of these added heat pump-ready changes to their projects, 175,000 more homes a year would become more ready.

How to get homes more ready for heat pumps? (part 3)

3. Create a targeted scheme to guide homeowners towards heat pumps

Even if some aspects of getting homes heat pump ready were made smoother as suggested above, it is still worth exploring how to enable homeowners to proactively prepare for a heat pump. Homebuyers and those planning renovations are in the best position to think about heat pump readiness as they are already making changes to their home.

People typically don't know what a heat pump installation will involve for them until they receive a quote. Providing personalised and reliable information at the right time could help them prepare their home over time. A ‘heat pump readiness’ assessment – like the one we tested with homeowners – could offer a step-by-step guide toward the transition, linking necessary actions to natural events like renovations and boiler servicing so that the steps feel timely and manageable. In response, households could:

- reserve or create space for a hot water tank, or avoid exchanging a boiler for a combi boiler without a water tank

- if exchanging a water cylinder, choose one that is heat pump-suitable

- if doing work in the garden, keep space for an outdoor unit

- if installing new radiators or wet underfloor heating, choose options that are compatible with a heat pump

Who should give the advice and when?

Our research suggests that consumers tend to have more confidence in advice given by a credible independent body as opposed to someone who installs heat pumps (or accompanying measures such as insulation). Ideally, any heat pump-ready service would be delivered in partnership with an independent body.

Local authorities or local retrofit partnerships could leverage their existing relationship with residents. They could contact every new homeowner and refer them to a website where they would be instructed to complete a simple survey, without anyone needing to come into the home. Alternatively, they could send out general information about heat pump readiness to every new homeowner. If data about boiler age currently held by the Gas Safe Register were released to governments, then local authorities could also target households whose boiler is nearing the end of its life, and tailor their recommendations based on boiler age. Local authorities could include individual information about permitted development and connection readiness provided by the DNO in their reports to households.

The future Warm Homes Agency is described in the Warm Homes Plan as a digital-first advice and information platform that will act as a national spine for consumer advice. Such a body should be able to provide guidance on making homes ready for heat pumps. Implementing a set of simple principles, households could receive trustworthy “readiness” guidance.

Energy suppliers could be well placed to deliver energy assessments since they have the resources needed and an existing relationship with their customers. With a simple assessment not requiring a visit by a specialist, the company could simply process data provided by the customer or outsource data collection to a smart meter installer. Beyond smart meter installations, other relevant trigger points are solar panel, battery or EV charger installations and new customer acquisition (people often switch suppliers when they move homes, which is a relevant time for thinking about a heat pump).

Surveyors could also play a role. About 1 in 4 homebuyers commission a survey of their new property to check for faults and risks (while Home Reports are legally mandated for all sold properties in Scotland). Surveyors are regulated by RICS (Royal Institution of Chartered Surveyors) and could be mandated to add a standardised heat pump readiness assessment to their routine.

How detailed should the advice be?

It is difficult to design a heat pump readiness advice scheme that is accurate and personalised, whilst limiting costs. Using home heating professionals to deliver heat pump readiness advice and requiring a home visit adds significant cost.

Using a standardised photo and video-based tool that the homeowner or anyone who isn’t a qualified heating engineer would lower costs. This approach could enable radiator sizing recommendations and estimates of the impact of any insulation, but couldn’t then, under current regulations, be used for later heat pump design.

Many companies are already relying on smart-scanning tools for heat-loss calculations. If large installers trusted the way other firms calculate heat loss, or if several installers could rely on the same third-party calculations, homeowners could have much longer and smoother journeys toward heat pumps – for example, getting a survey done now and a heat pump fitted years later by a different company. For that to work, the installer taking on the job would need confidence that the original survey met current MCS requirements, because they remain responsible for the accuracy of the heat-loss calculation when issuing the MCS certificate.

Our user research suggests that homeowners would prefer the report to include reliable cost projections. But then, in most cases, the type of homeowner who would benefit most from a heat loss survey that can be used for heat pump system design would be better served by getting a heat pump quote from an installer instead of a ‘heat pump readiness’ report. Many holistic independent assessments are also available on the market already, commercially (such as Warmur or Thermly) or locally, sometimes supported by local authorities (Loco Homes Retrofit, Futureproof).

For the rest of homeowners – those who are not close to getting a heat pump – simple information about what heat pumps are and what they generally need to function in a home might then suffice, such as advice to reserve space for a hot water cylinder.

Can readiness advice be cost-effective?

To reach households that are not yet interested in getting a heat pump, government funding would be needed for developing or purchasing a tool that gives people readiness guidance and for communicating with householders. The more personalised the advice is, the more costly it would be, while also requiring more engagement from the householder, who, if they aren’t considering a heat pump yet, should not be expected to engage actively.

Guidance on preparing homes for heat pumps is needed. But this advice should be narrowly targeted, should not demand the involvement of specialist tradespeople, nor require significant effort from homeowners.

Currently, one in three homeowners say they might consider a heat pump if they need to change their heating in the next year. With ~19 million owner-occupied households, that makes 6.3 million households. Around 1 million existing homes are sold each year. If only 20% of them received heat pump readiness advice – 200,000 homeowners reached each year – many more would likely start considering a heat pump. Those who decide they can start making their home ready in advance would get the additional benefit of spacing out work on their home and reducing mental load.

The potential impact of heat pump readiness

The potential impact of heat pump readiness

There are several routes by which heat pump readiness interventions could speed up heat pump adoption:

- Eliminating system barriers: Removing administrative delays (DNO approval, EPC requirement, and planning permission delays) will enable quick, “distress purchase” installations.

- As heat pumps become more common, faster to install, and cheaper to run, more replacements will happen under time pressure when a boiler fails. In those cases, even small delays can be decisive. Removing these barriers could enable tens of thousands of additional distress purchase installations.

- Reducing friction: A homeowner takes some of the recommended actions, making their home more ready, and a future heat pump installation easier, faster and cheaper.

- As with all solutions that target individual upgrades, it is difficult to predict, however, how home readiness will affect a decision to get a heat pump. Important factors – the cost of the heat pump and electricity prices – are often leading people to favour gas boilers. But for some households, removing a few hundred pounds of cost and several days of disruption may be enough to tip the decision.

- Increasing familiarity and confidence: A homeowner learns about heat pumps and the steps to get one, and is then more likely to consider a heat pump.

- General awareness of heat pumps is still low. Giving guidance on the steps to install one could make people more likely to get a heat pump, even if they don’t implement any readiness steps.

Our conclusions

Our conclusions

Heat pump installations involve multiple technical and administrative steps that add cost, time and stress for both installers and consumers. Most homeowners only think about heating when their boiler breaks, at which point they default to replacing it with another gas boiler. If households were to take some preparatory steps before their boiler breaks, heat pumps would become easier and faster to install. To enable faster heat pump adoption, we need to streamline administrative processes that cause delays, enable physical upgrades to happen at convenient moments when work is already planned, and provide information so households can plan ahead with confidence.

We have explored three ways to move households toward heat pump readiness and identified the most promising avenues:

- Removing administrative barriers as soon as possible is essential. They affect most installations and block rapid switches when boilers fail.

- Speed up DNO approvals: Give DNOs clear incentives to meet challenging key performance indicators for quick, low-carbon technology approvals.

- Reduce the number of properties that need planning permission: Further extend permitted development rights to reduce the need for homeowners to seek planning permission.

- Enabling upgrades at convenient touchpoints would remove friction and mental load for some households.

- Pre-emptively undertake electrical upgrades: Smart meter installations and renovations could offer natural moments for electrical upgrades. Energy suppliers could proactively check household electrics and make homes more ready for a heat pump.

- Incentivise heat pump readiness as part of existing works: Innovators and heat pump providers should explore incentives for builders, architects and other renovation actors to promote readiness through guidance and product labelling.

- Avoid blanket mandates for low-temperature systems: The enforcement challenges and fraud risk make this impractical, especially as high-temperature heat pumps reduce the need for radiator upgrades.

- Homebuyers and renovators need simple guidance to become aware of the steps needed to become heat pump ready and to avoid counterproductive choices (like removing hot water cylinders). Our testing showed readiness reports could help. Publicly subsidised simple information for new homeowners is likely to be more practical than detailed heat loss surveys.

As adoption accelerates, more switches will happen under time pressure. Removing DNO delays and enabling preparatory electrical work will determine whether heat pumps become the default option at gas boiler failure. Readiness must reduce hassle rather than add it – working in the background, piggybacking on planned work, or providing simple guidance at natural decision points.